Description

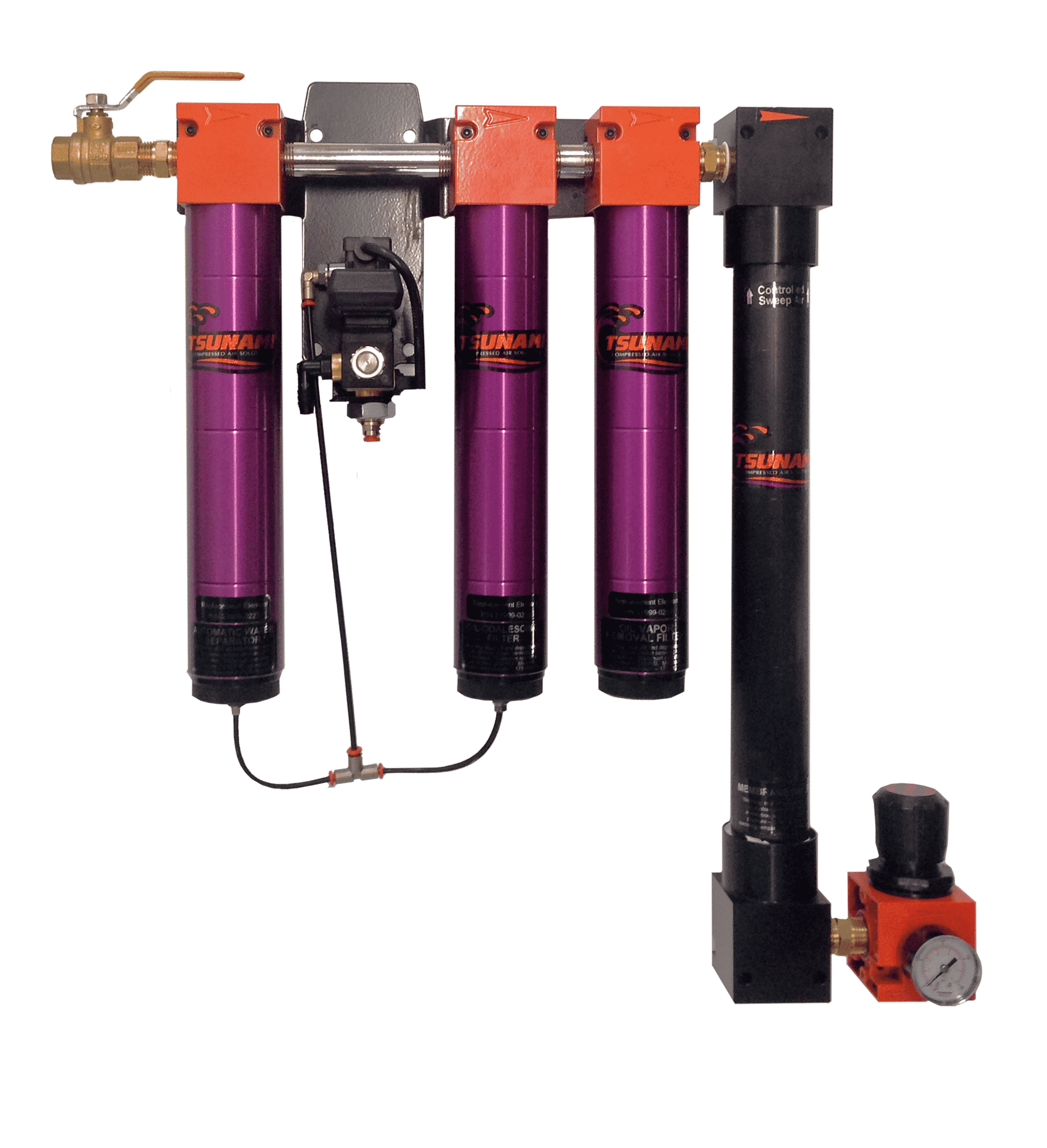

20 Series CMM Filtration System with Membrane Dryer – 20 SCFM

#21999-0524

The Number One cause of down time and repair is oil and contamination from your compressed air system. It causes fouling of the air lines and air bearings inside your CMM. This system design includes a Tsunami Membrane Dryer which will lower the dew point of the incoming air. Use in locations where CMM is located on the shop floor or when very wet hot air enters the inspection room from the plant.

- Reduce down time and expensive repairs

- Maintain accuracy

- Complete system installs in minutes

- First stage removes water and oil down to 10 micron

- Second stage oil coalescer removes oil mist and aerosol down to 0.01 micron; oil removal down to .001 ppm

- Third stage removes oil vapor/smell down to 0.003 micron

- Lowest pressure drop of any filter package (1.8 psid)

- Micro-flex element capacity 3 times larger (Efficiency: Dry 99.949 Saturated 99.920)

- Grade “D” instrument air meets HEPA air quality standards

- First stage Stainless Steel Element Never Needs Changing

- Second & Third Stage Elements: Change Every 6 Months, Under Normal Conditions.

| Specifications | |

| Flow: | 20 scfm |

| Port Size: | 1/2″ NPT |

| ISO Class: | <1 |

| Micron Rating: | 0.01 Micron |

| Oil Carry Over PPM: | 0.001 |

| Drain Type: | Solenoid |

| Max. Pressure: | 250 psi |

|

Safety Information - Proposition 65

Safety Information - Proposition 65

Reviews

There are no reviews yet.